Файлы

Раздел содержит файлы для скачивания по теме вилочных погрузчиков.

Инструкции по эксплуатации |

Инструкции по эксплуатации вилочных погрузчиковДоступны для скачивания инструкции и руководства для погрузчиков: Komatsu, Toyota, Yale. Все инструкции для вилочных погрузчиков содержат следующую информацию:

Руководство оператора штабелераДоступно для скачивания руководство оператора для штабелера BT. Кроме стандартной информации инструкция содержит цифровые коды предупреждений и ошибок. |

|

Руководство оператора штабелера BT SPE125 SPE160 |

| Правила техники безопасности Описание штабелера Технические данные Основные узлы и детали Органы управления Цифровые коды ошибок Вождение Перемещение грузов Аккумуляторная батарея Техобслуживание батареи График проведения планового техобслуживания Таблица смазки различных узлов и деталей |

|

Дата: 2015-01-07 18:06:12 Размер: 2.3 Мб Скачано: 17264 |

| Вернуться |

| Список категорий |

Toyota Forklift Error Codes List pdf Download

Toyota Forklift 8FD/FG series Error Codes Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 1 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 2 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 3 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 4 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 5 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 6 Download

MODEL APPLICATION:

7FBCU15, 7FBCU18, 7FBCU20, 7FBCU25, 7FBCU30, 7FBCU32 7FBCU35, 7FBCU45, 7FBCU55, 7FBCHU18, 7FBCHU25 7FBEU15, 7FBEU18, 7FBEU20, 7FBEHU18, 7FGU15, 7FGU18 7FGU20, 7FGU25, 7FGU30, 7FGU32, 7FDU15,

7FDU18, 7FDU20 7FDU25, 7FDU30, 7FDU32, 8FGU15, 8FGU18, 8FGU20, 8FGU25 8FGU30, 8FGU32, 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30 8FDU32, 7FGCU15, 7FGCU18, 7FGCU20, 7FGCSU20, 7FGCU25 7FGCU30, 7FGCU32,

8FGCU18, 8FGCU20, 8FGCSU20, 8FGCU25 8FGCU30, 8FGCU32, 7FGU35, 7FDU35, 7FGKU40, 7FDKU40 7FGU45, 7FDU45, 7FGAU50, 7FDAU50, 7FGU60, 7FDU60, 7FGU70 7FDU70, 7FGU80, 7FDU80, 7FGCU35, 7FGCU45, 7FGCU55

7FGCU60, 7FGCU70

GENERAL INFORMATION:

All three error codes are for the same condition. • A5 is for sit-down electric trucks (Class I) • A5-1 is for 8-Series internal combustion trucks (Class IV & V) • 1-1 is for 7-Series

internal combustion trucks (Class IV & V) with OPSS (Operator Presence Sensing System)

Further information concerning these codes can be found in the following manuals:

7FBCU15-55 ►OPSS Manual CU335 page 3-9 7FBEU15-20 ►OPSS Manual CU341 page 1-10 7FGCU15, 18, S20 ►OPSS Manual CU042 page 1-19 7FGU15-32, 7FDU15-32, 7FGCU20-32 ►OPSS Manual CU040 page 1-18

7FGU35-80, 7FDU35-80, 7FGCU35-70 ►OPSS Manual CU041 page 1-17 8FGCU15, 18, S20 ►Service manual 00700-X8880-71 page 19.1-82 8FGU15-32, 8FDU15-32, 8FGCU20-32 ►Service manual 00700-X8880-71 page

19-111

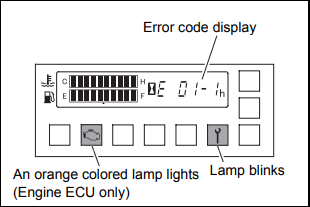

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method The diagnosis is displayed by means of an error code as shown in the illustration to the left, and by the lights turning on. When the ignition key switch is turned ON,

the lamp lights once to allow checking for the bulb, and then turns off again if the status is normal. With the ignition key switch ON, if an abnormality is detected when the vehicle is stopped,

travelling or performing meterials handling operations, an error code is displayed and the lamps turn on as a warning. When this happens, stop the vehicle immediately and check the error code.

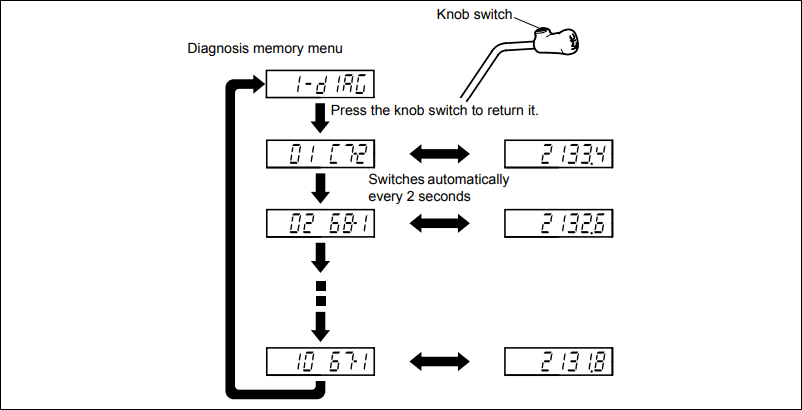

2. Diagnosis memory display method To display the diagnosis memory display, there are a method using the hour meter and tilt lever, a method using the optional display, and a method using a

plug-in analyzer. Here the display method using the hour meter and tilt lever is described. (1) From the main menu, display the diagnosis memory menu. For how to display the main menu, refer to

page 18-30. (2) A diagnosis No. and error code are displayed each time the knob switch is pressed and released. Each error code and the time at which it occurred are displayed alternately at 2

second intervals.

(3) Connect the matching connector and turn the ignition key switch OFF.

LIST OF DIAGNOSIS CODES

Translated from Indonesian!

Original text error codes Download

41-1 Matching connector abnormal Only the Connector display is faulty

Matching cable is broken

Controller is broken

51-1 Speed sensor abnormal Speed indicator keeps showing 0 km/h Connector is faulty

51-2 Rear wheel swing control Damaged connector cable

Steer knob is not in position Speed sensor is broken

Controller is broken

52-1 Yaw rate sensor abnormal Rear wheel swing control is limited. Broken connector

52-2 Connector cable is damaged

52-3 Yaw rate sensor is faulty

Controller is broken

54-1 Swing lock solenoid abnormal Rear wheel swing control is limited. Broken connector

Broken connector cable

Swing lock solenoid is broken

Controller is broken

61-1 Load sensor abnormal Rear wheel swing control is limited. Broken connector

61-2 Control mast function is partially restricted Connector cable is damaged

Drive control function is limited (MFD opt) Load sensor is faulty

Load indicator does not appear on the display (MFD) The controller is broken

Error mode Symptoms on forklift Possible causes

damaged

62-1 Tilt angle sensor abnormal Mast control function is partially restricted Connector is faulty

62-2 Connector cable is damaged

Broken tilt angle sensor

Controller is broken

63-1 Tilt lever switch abnormal Mast control function is partially restricted Connector is faulty

63-2 Forward tilt switch is broken

63-3 Backward tilt switch is broken

Broken cable

Faulty switch installation

Controller is broken

64-1 Lift lock solenoid abnormal Fork won’t come down Connector is broken

Broken connector cable

Broken lift lock solenoid

Controller is broken

65-1 Tilt control solenoid abnormal Forward tilt cannot operate, but Connector is damaged

backward tilt operable. Broken connector cable

Broken tilt control solenoid

Controller is broken

66-1 Abnormal matching measurement value The control mast function is partially restricted. The horizontal tilt angle value does not match.

Tilt forward angle value

it is not in accordance with.

Measuring value of load sensor

it is not in accordance with.

67-1 Lifting height switch abnormal Partial rearwheel swing control function Faulty connector

restricted. Broken connector cable

Mast control function is partially restricted Lifting height swt is broken

Drive control function is restricted Controller is faulty

Load indicator display changes IG fuse blown

68-1 Lift switch abnormal Fork won’t come down Connector is broken

68-2 Raising lift swt is broken

68-3 Lowering lift swt is broken

Broken connector cable

The swt elevator installation is broken

Controller is broken

Error mode Symptoms on the forklift Possible cause of failure

69-1 Backward tilt lock solenoid Backward tilt does not operate Connector is faulty

abnormal Connector cable is damaged

Backward tilt lock solenoid is faulty.

Controller is broken

71-1 Tire angle sensor abnormal Steer knob is not in position Connector is faulty

71-2 Connector cable is damaged

Broken sensor

tire angle sensor joint,

rear axle link syst. damaged

Controller is broken

72-1 Steering angle sensor abnormal Steer knob is not in position Connector is faulty

72-2 Connector cable is damaged

72-3 Sensor is faulty

72-4 Controller is faulty

73-1 Abnormal solenoid knob position Steer knob out of position Connector is faulty

Broken connector cable

Broken solenoid

Controller is broken

74-1 Measuring value of matching tire angle Steer knob is not in position Matching value

wheel alignment error no in accordance

A5-1 Seat switch abnormal Drive & hydraulic system can operate Connector is faulty

even if the operator is not sitting in the operating chair The connector cable is damaged

Broken switch

Controller is broken

A7-1 Abnormal brake switch Function of partially restricted drive control Connector is faulty

Broken brake switch

Broken connector cable

Controller is broken

AF-1

AF-2

AF-3

AF-4

AF-5

AF-6

AF-7

AF-8 CPU abnormal All control functions are unstable Controller is faulty

C7-1 Shift lever switch abnormal Cannot be positioned to neutral Connector is faulty

C7-2 Drive control function is partially restricted Forward switch is faulty

Reverse switch is broken

Broken cable

Faulty switch installation

Controller is broken

CA-1 Forward-reverse travel Torque Drive system and hydraulic system can Connector damaged

converter relay abnormal is operated even when operator is not seated Forward travel cable

the relay operator seat is broken

Forward travel relay

damaged

reverse travel cable

broken relay

Reverse travel relay

damaged

Controller is broken

EC-1 Unload solenoid abnormal Drive system and hydraulic system can Connector is faulty

operated even if the operator is not seated Connector cable is damaged

in operator seat Unload solenoid is broken

Controller is broken

F1-1 Combination meter abnormal Problem on the display Connector is damaged

F1-2 Hour meter cable is damaged

Hour meter is broken

Controller is broken

F4-1~8 CPU error CPU abnormal Multi-function board

broken display

H1-1 Lift lever potentiometer abnormal Lift cannot operate Connectro is faulty

H1-2 The potentiometer wire is damaged

H1-3 Potentiometer is broken

H1-4 Controller is broken

H1-5 Fuse blown

H2-1 Tilt lever potentiometer abnormal Tilt does not operate Connectro is faulty

H2-2 The potentiometer wire is damaged

H2-3 Potentiometer is broken

H2-4 Controller is broken

H2-5 Fuse blown

H3-1 Attachment 1 lever potentiometer Attachment 1 does not operate Connectro is faulty

H3-2 abnormal Potentiometer cable is damaged

H3-3 The potentiometer is faulty

H3-4 Controller is broken

H3-5 Fuse blown

H4-1 Attachment 2 lever potentiometer Attachment 2 does not operate Connectro is damaged

H4-2 abnormal Potentiometer cable is damaged

H4-3 The potentiometer is faulty

H4-4 Controller is broken

H4-5 Fuse blown

H5-1 Lift solenoid abnormal Elevator may not operate Faulty connector

H5-2 Elevator cable (PUSH) is damaged

Solenoid lift (PUSH) is broken

Elevator cable (PULL) is broken

Solenoid lift (PULL) is broken

Controller is broken

H6-1 Solenoid Tilt Abnormal Tilt may not operate Connector is faulty

H6-2 Faulty tilt (PUSH) cable

Solenoid tilt (PUSH) faulty

Broken tilt (PULL) cable

Solenoid tilt (PULL) faulty

Controller is broken

H7-1 Attachment 1 abnormal solenoid Attachment 1 may not work Connector is damaged

H7-2 operating Att 1 (PUSH) cable is faulty

Solenoid Att 1 (PUSH) is faulty

Att 1 (PULL) cable is damaged

Solenoid Att 1 (PULL) is faulty

Controller is broken

H8-1 Attachment 2 abnormal solenoid Attachment 2 may not work Connector is damaged

H8-2 operating Att 2 (PUSH) cable is faulty

Solenoid Att 2 (PUSH) is faulty

Att 2 (PULL) cable is damaged

Solenoid Att 2 (PULL) is faulty

Controller is broken

HA-1 3/4-way change relay abnormal Attachment transfer is not possible Connector is damaged

operating Relay cable 1 is damaged

Relay 1 is broken

Relay cable 2 is damaged

Relay 2 is broken

Controller is broken

Error mode Symptoms on forklift Possible causes

broken WARNING LIST

IF THE WRENCH LAMP IS ON AND WITH THESE SYMPTOMS BELOW ON

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

01-01 |

01-01 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) rich |

The engine speed is unstable and it may stop. |

|

01-02 |

01-02 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) lean |

|

|

01-03 |

01-03 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) rich |

|

|

01-04 |

01-04 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) lean |

|

|

01-05 |

01-05 |

Blinking |

4Y-ECS |

02 sensor open abnormality |

The engine speed is unstable and it may stop. |

|

01-06 |

01-06 |

Blinking |

4Y-ECS |

02 sensor heater open abnormality |

Display only |

|

02-01 |

02-01 |

Blinking |

4Y-ECS |

Intake temperature sensor open abnormality |

The engine may have a problem at low temperatures. |

|

02-02 |

02-02 |

Blinking |

4Y-ECS |

Intake temperature sensor short abnormality |

|

|

03-01 |

03-01 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor open abnormality |

The engine may have a problem |

|

03-02 |

03-02 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor short abnormality |

|

|

04-01 |

04-01 |

Blinking |

4Y-ECS |

Coolant temperature sensor open abnormality |

The engine may have a problem at low temperatures. |

|

04-02 |

04-02 |

Blinking |

4Y-ECS |

Coolant temperature sensor short abnormality |

|

|

05-01 |

05-01 |

Blinking |

4Y-ECS |

Throttle position sensor 1 open abnormality |

Limting speed of traveling and materials handling due to limited engine power output |

|

05-02 |

05-02 |

Blinking |

4Y-ECS |

Throttle position sensor 1 short abnormality |

|

|

05-03 |

05-03 |

Blinking |

4Y-ECS |

Throttle position sensor 2 open abnormality |

|

|

05-04 |

05-04 |

Blinking |

4Y-ECS |

Throttle position sensor 2 short abnormality |

|

|

05-05 |

05-05 |

Blinking |

4Y-ECS |

Throttle position sensor offset abnormality |

|

|

05-06 |

05-06 |

Blinking |

4Y-ECS |

Throttle position sensor out of range error |

|

|

06-01 |

06-01 |

Blinking |

4Y-ECS |

Throttle motor drive circuit open abnormality |

Limting speed of traveling and materials handling due to limited engine power output |

|

06-02 |

06-02 |

Blinking |

4Y-ECS |

Throttle motor drive circuit short abnormality |

|

|

06-03 |

06-03 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit open abnormality |

|

|

06-04 |

06-04 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit short abnormality |

|

|

06-05 |

06-05 |

Blinking |

4Y-ECS |

Throttle motor seizing abnormality |

|

|

06-06 |

06-06 |

Blinking |

4Y-ECS |

Electronic throttle system error |

|

|

07-01 |

07-01 |

Blinking |

4Y-ECS |

Air-fuel ratio motor open abnormality |

The engine speed is unstable and it may stop. |

|

08-01 |

08-01 |

Blinking |

4Y-ECS |

Low voltage (battery line open) error |

Display only |

|

09-01 |

09-01 |

Blinking |

4Y-ECS |

Ignition signal error |

The engine speed is unstable and it may stop. |

|

OA-1 |

OA-1 |

Blinking |

4Y-ECS |

Fuel specification determination signal error |

Display only |

|

OA-2 |

OA-2 |

Blinking |

4Y-ECS |

Fuel specification changeover switch error |

Display only |

|

OA-3 |

OA-3 |

Blinking |

4Y-ECS |

Fuel specification type unmatch |

Engine may stop |

|

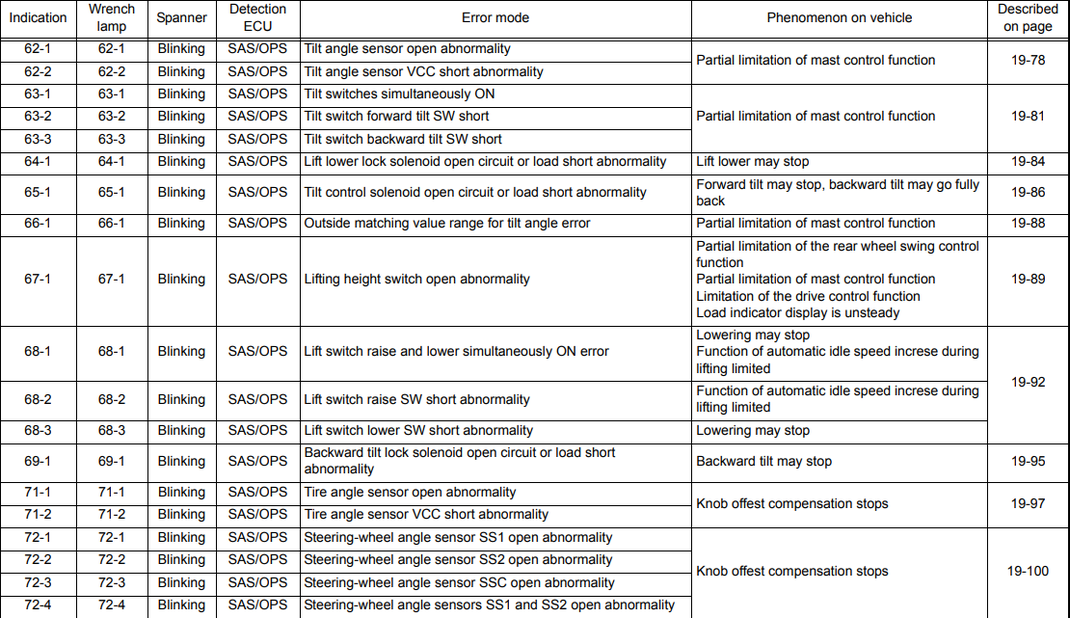

62-1 |

62-1 |

Blinking |

SAS/OPS |

Tilt angle sensor open abnormality |

Partial limitation of mast control function |

|

62-2 |

62-2 |

Blinking |

SAS/OPS |

Tilt angle sensor VCC short abnormality |

|

|

63-1 |

63-1 |

Blinking |

SAS/OPS |

Tilt switches simultaneously ON |

Partial limitation of mast control function |

|

63-2 |

63-2 |

Blinking |

SAS/OPS |

Tilt switch forward tilt SW short |

|

|

63-3 |

63-3 |

Blinking |

SAS/OPS |

Tilt switch backward tilt SW short |

|

|

64-1 |

64-1 |

Blinking |

SAS/OPS |

Lift lower lock solenoid open circuit or load short abnormality |

Lift lower may stop |

|

65-1 |

65-1 |

Blinking |

SAS/OPS |

Tilt control solenoid open circuit or load short abnormality |

Forward tilt may stop, backward tilt may go fully back |

|

66-1 |

66-1 |

Blinking |

SAS/OPS |

Outside matching value range for tilt angle error |

Partial limitation of mast control function |

|

67-1 |

67-1 |

Blinking |

SAS/OPS |

Lifting height switch open abnormality |

Partial limitation of the rear wheel swing control function |

|

68-1 |

68-1 |

Blinking |

SAS/OPS |

Lift switch raise and lower simultaneously ON error |

Lowering may stop |

|

68-2 |

68-2 |

Blinking |

SAS/OPS |

Lift switch raise SW short abnormality |

Function of automatic idle speed increse during lifting limited |

|

68-3 |

68-3 |

Blinking |

SAS/OPS |

Lift switch lower SW short abnormality |

Lowering may stop |

|

69-1 |

69-1 |

Blinking |

SAS/OPS |

Backward tilt lock solenoid open circuit or load short abnormality |

Backward tilt may stop |

|

71-1 |

71-1 |

Blinking |

SAS/OPS |

Tire angle sensor open abnormality |

Knob offest compensation stops |

|

71-2 |

71-2 |

Blinking |

SAS/OPS |

Tire angle sensor VCC short abnormality |

|

|

72-1 |

72-1 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS1 open abnormality |

Knob offest compensation stops |

|

72-2 |

72-2 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS2 open abnormality |

|

|

72-3 |

72-3 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SSC open abnormality |

|

|

72-4 |

72-4 |

Blinking |

SAS/OPS |

Steering-wheel angle sensors S51 and SS2 open abnormality |

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

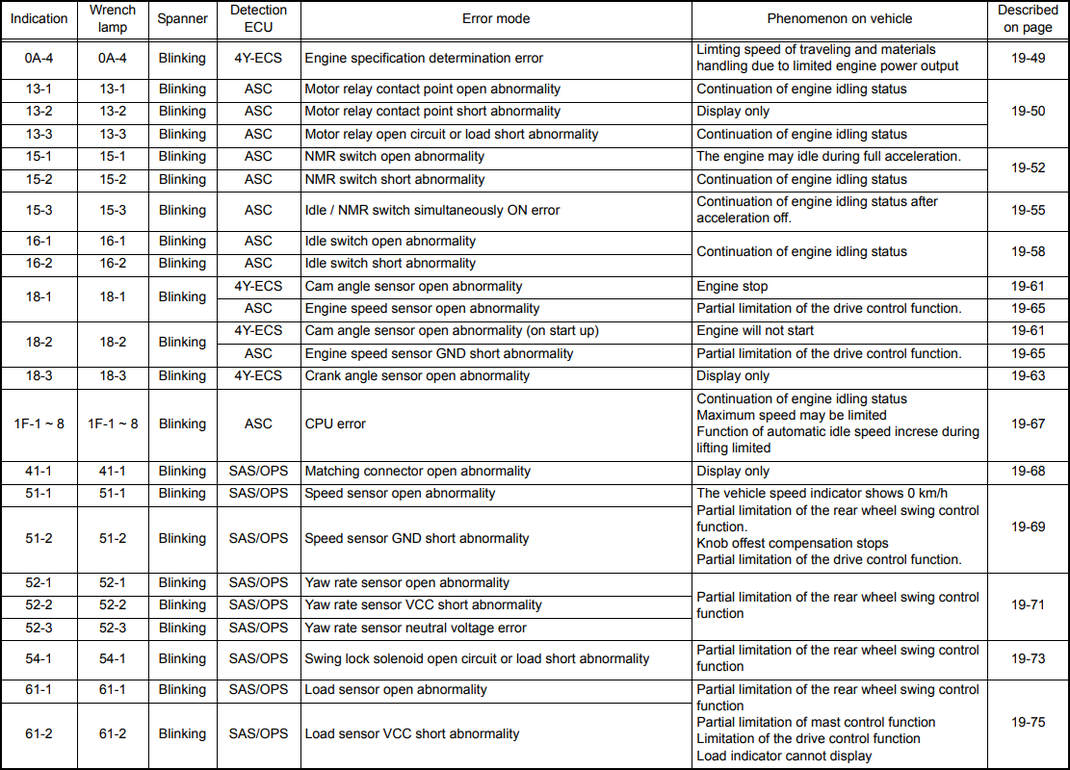

OA-4 |

OA-4 |

Blinking |

4Y-ECS |

Engine specification determination error |

Limting speed of traveling and materials handling due to limited engine power output |

|

13-1 |

13-1 |

Blinking |

ASC |

Motor relay contact point open abnormality |

Continuation of engine idling status |

|

13-2 |

13-2 |

Blinking |

ASC |

Motor relay contact point short abnormality |

Display only |

|

13-3 |

13-3 |

Blinking |

ASC |

Motor relay open circuit or load short abnormality |

Continuation of engine idling status |

|

15-1 |

15-1 |

Blinking |

ASC |

NMR switch open abnormality |

The engine may idle during full acceleration. |

|

15-2 |

15-2 |

Blinking |

ASC |

NMR switch short abnormality |

Continuation of engine idling status |

|

15-3 |

15-3 |

Blinking |

ASC |

Idle / NMR switch simultaneously ON error |

Continuation of engine idling status after acceleration off. |

|

16-1 |

16-1 |

Blinking |

ASC |

Idle switch open abnormality |

Continuation of engine idling status |

|

16-2 |

16-2 |

Blinking |

ASC |

Idle switch short abnormality |

|

|

18-1 |

18-1 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality |

Engine stop |

|

ASC |

Engine speed sensor open abnormality |

Partial limitation of the drive control function. |

|||

|

18-2 |

18-2 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality (on start up) |

Engine will not start |

|

ASC |

Engine speed sensor GND short abnormality |

Partial limitation of the drive control function. |

|||

|

18-3 |

18-3 |

Blinking |

4Y-ECS |

Crank angle sensor open abnormality |

Display only |

|

1 F-1 — 8 |

1 F-1 — 8 |

Blinking |

ASC |

CPU error |

Continuation of engine idling status |

|

41-1 |

41-1 |

Blinking |

SAS/OPS |

Matching connector open abnormality |

Display only |

|

51-1 |

51-1 |

Blinking |

SAS/OPS |

Speed sensor open abnormality |

The vehicle speed indicator shows 0 km/h Partial limitation of the rear wheel swing control function. |

|

51-2 |

51-2 |

Blinking |

SAS/OPS |

Speed sensor GND short abnormality |

|

|

52-1 |

52-1 |

Blinking |

SAS/OPS |

Yaw rate sensor open abnormality |

Partial limitation of the rear wheel swing control function |

|

52-2 |

52-2 |

Blinking |

SAS/OPS |

Yaw rate sensor VCC short abnormality |

|

|

52-3 |

52-3 |

Blinking |

SAS/OPS |

Yaw rate sensor neutral voltage error |

|

|

54-1 |

54-1 |

Blinking |

SAS/OPS |

Swing lock solenoid open circuit or load short abnormality |

Partial limitation of the rear wheel swing control function |

|

61-1 |

61-1 |

Blinking |

SAS/OPS |

Load sensor open abnormality |

Partial limitation of the rear wheel swing control function |

|

61-2 |

61-2 |

Blinking |

SAS/OPS |

Load sensor VCC short abnormality |

|

Indication |

lamp lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

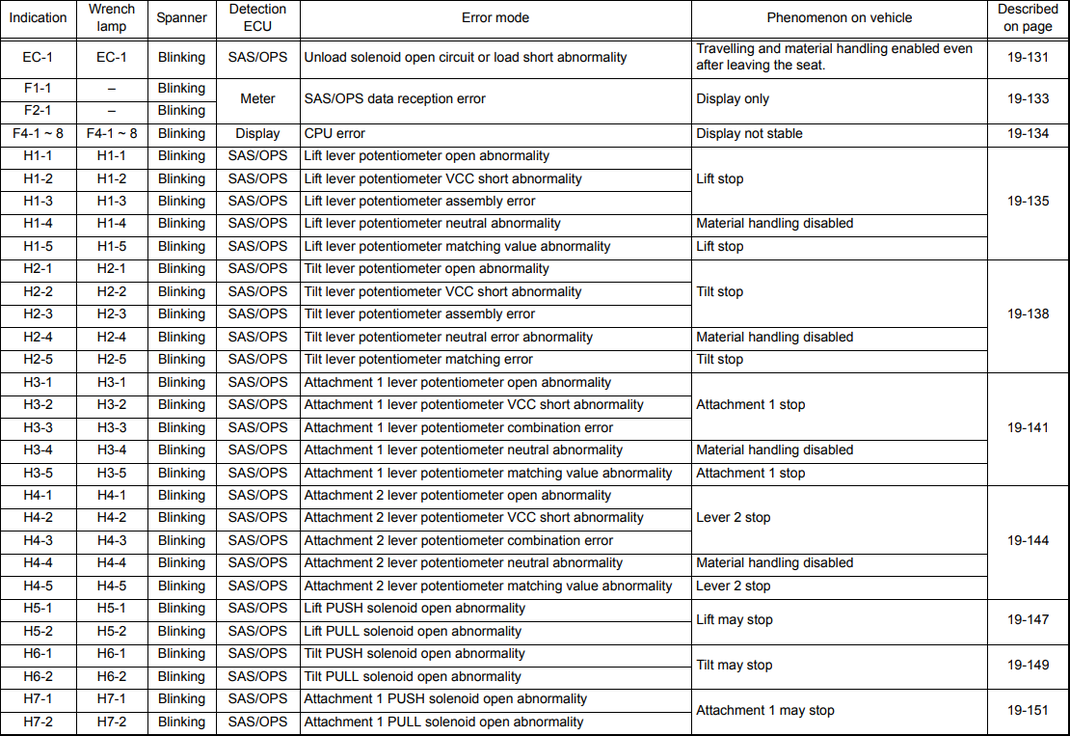

EC-1 |

EC-1 |

Blinking |

SAS/OPS |

Unload solenoid open circuit or load short abnormality |

Travelling and material handling enabled even after leaving the seat. |

|

F1-1 |

— |

Blinking |

Meter |

SAS/OPS data reception error |

Display only |

|

F2-1 |

— |

Blinking |

|||

|

F4-1 — 8 |

F4-1 — 8 |

Blinking |

Display |

CPU error |

Display not stable |

|

H1-1 |

H1-1 |

Blinking |

SAS/OPS |

Lift lever potentiometer open abnormality |

Lift stop |

|

H1-2 |

H1-2 |

Blinking |

SAS/OPS |

Lift lever potentiometer VCC short abnormality |

|

|

H1-3 |

H1-3 |

Blinking |

SAS/OPS |

Lift lever potentiometer assembly error |

|

|

H1-4 |

H1-4 |

Blinking |

SAS/OPS |

Lift lever potentiometer neutral abnormality |

Material handling disabled |

|

H1-5 |

H1-5 |

Blinking |

SAS/OPS |

Lift lever potentiometer matching value abnormality |

Lift stop |

|

H2-1 |

H2-1 |

Blinking |

SAS/OPS |

Tilt lever potentiometer open abnormality |

Tilt stop |

|

H2-2 |

H2-2 |

Blinking |

SAS/OPS |

Tilt lever potentiometer VCC short abnormality |

|

|

H2-3 |

H2-3 |

Blinking |

SAS/OPS |

Tilt lever potentiometer assembly error |

|

|

H2-4 |

H2-4 |

Blinking |

SAS/OPS |

Tilt lever potentiometer neutral error abnormality |

Material handling disabled |

|

H2-5 |

H2-5 |

Blinking |

SAS/OPS |

Tilt lever potentiometer matching error |

Tilt stop |

|

H3-1 |

H3-1 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer open abnormality |

Attachment 1 stop |

|

H3-2 |

I-13-2 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer VCC short abnormality |

|

|

H3-3 |

H3-3 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer combination error |

|

|

H3-4 |

H3-4 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer neutral abnormality |

Material handling disabled |

|

H3-5 |

H3-5 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer matching value abnormality |

Attachment 1 stop |

|

H4-1 |

H4-1 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer open abnormality |

Lever 2 stop |

|

H4-2 |

H4-2 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer VCC short abnormality |

|

|

H4-3 |

H4-3 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer combination error |

|

|

H4-4 |

H4-4 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer neutral abnormality |

Material handling disabled |

|

H4-5 |

H4-5 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer matching value abnormality |

Lever 2 stop |

|

H5-1 |

H5-1 |

Blinking |

SAS/OPS |

Lift PUSH solenoid open abnormality |

Lift may stop |

|

H5-2 |

H5-2 |

Blinking |

SAS/OPS |

Lift PULL solenoid open abnormality |

|

|

H6-1 |

H6-1 |

Blinking |

SAS/OPS |

Tilt PUSH solenoid open abnormality |

Tilt may stop |

|

H6-2 |

H6-2 |

Blinking |

SAS/OPS |

Tilt PULL solenoid open abnormality |

|

|

H7-1 |

H7-1 |

Blinking |

SAS/OPS |

Attachment 1 PUSH solenoid open abnormality |

Attachment 1 may stop |

|

H7-2 |

H7-2 |

Blinking |

SAS/OPS |

Attachment 1 PULL solenoid open abnormality |

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

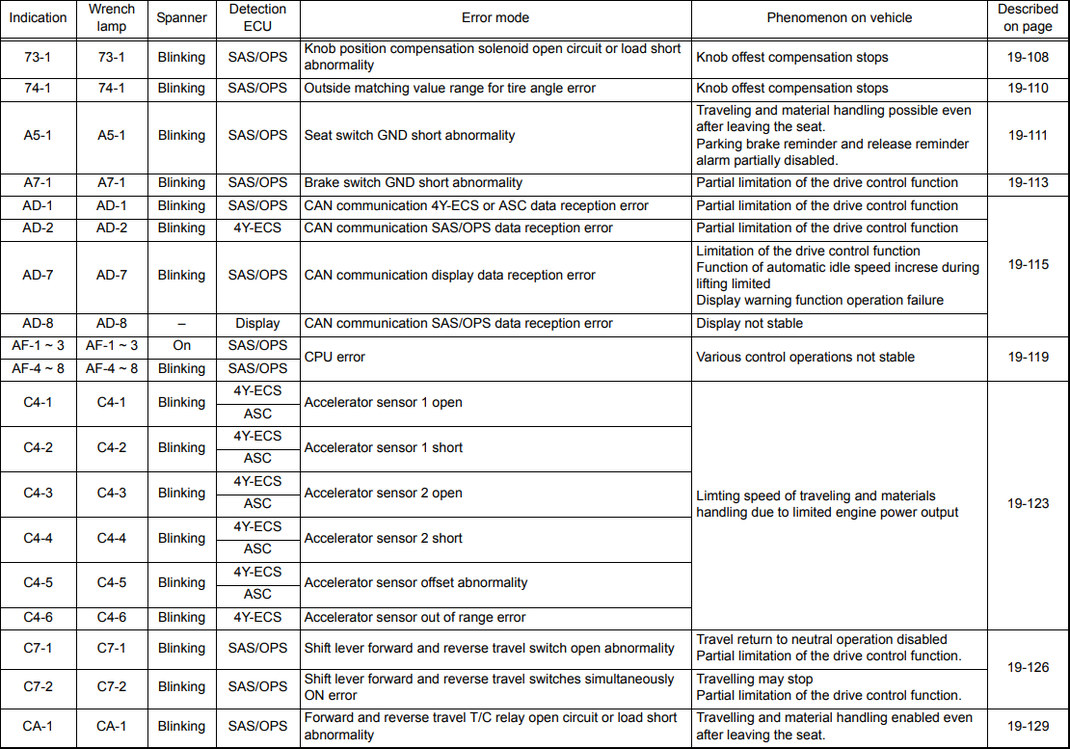

73-1 |

73-1 |

Blinking |

SAS/OPS |

Knob position compensation solenoid open circuit or load short abnormality |

Knob offest compensation stops |

|

74-1 |

74-1 |

Blinking |

SAS/OPS |

Outside matching value range for tire angle error |

Knob offest compensation stops |

|

A5-1 |

A5-1 |

Blinking |

SAS/OPS |

Seat switch GND short abnormality |

Traveling and material handling possible even after leaving the seat. |

|

A7-1 |

A7-1 |

Blinking |

SAS/OPS |

Brake switch GND short abnormality |

Partial limitation of the drive control function |

|

AD-1 |

AD-1 |

Blinking |

SAS/OPS |

CAN communication 4Y-ECS or ASC data reception error |

Partial limitation of the drive control function |

|

AD-2 |

AD-2 |

Blinking |

4Y-ECS |

CAN communication SAS/OPS data reception error |

Partial limitation of the drive control function |

|

AD-7 |

AD-7 |

Blinking |

SAS/OPS |

CAN communication display data reception error |

Limitation of the drive control function |

|

AD-8 |

AD-8 |

Display |

CAN communication SAS/OPS data reception error |

Display not stable |

|

|

AF-1 — 3 |

AF-1 — 3 |

On |

SAS/OPS |

CPU error |

Various control operations not stable |

|

AF-4 — 8 |

AF-4 — 8 |

Blinking |

SAS/OPS |

||

|

C4-1 |

C4-1 |

Blinking |

4Y-ECS |

Accelerator sensor 1 open |

Limting speed of traveling and materials handling due to limited engine power output |

|

ASC |

|||||

|

C4-2 |

C4-2 |

Blinking |

4Y-ECS |

Accelerator sensor 1 short |

|

|

ASC |

|||||

|

C4-3 |

C4-3 |

Blinking |

4Y-ECS |

Accelerator sensor 2 open |

|

|

ASC |

|||||

|

C4-4 |

C4-4 |

Blinking |

4Y-ECS |

Accelerator sensor 2 short |

|

|

ASC |

|||||

|

C4-5 |

C4-5 |

Blinking |

4Y-ECS |

Accelerator sensor offset abnormality |

|

|

ASC |

|||||

|

C4-6 |

C4-6 |

Blinking |

4Y-ECS |

Accelerator sensor out of range error |

|

|

C7-1 |

C7-1 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switch open abnormality |

Travel return to neutral operation disabled Partial limitation of the drive control function. |

|

C7-2 |

C7-2 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switches simultaneously ON error |

Travelling may stop |

|

CA-1 |

CA-1 |

Blinking |

SAS/OPS |

Forward and reverse travel T/C relay open circuit or load short abnormality |

Travelling and material handling enabled even after leaving the seat. |

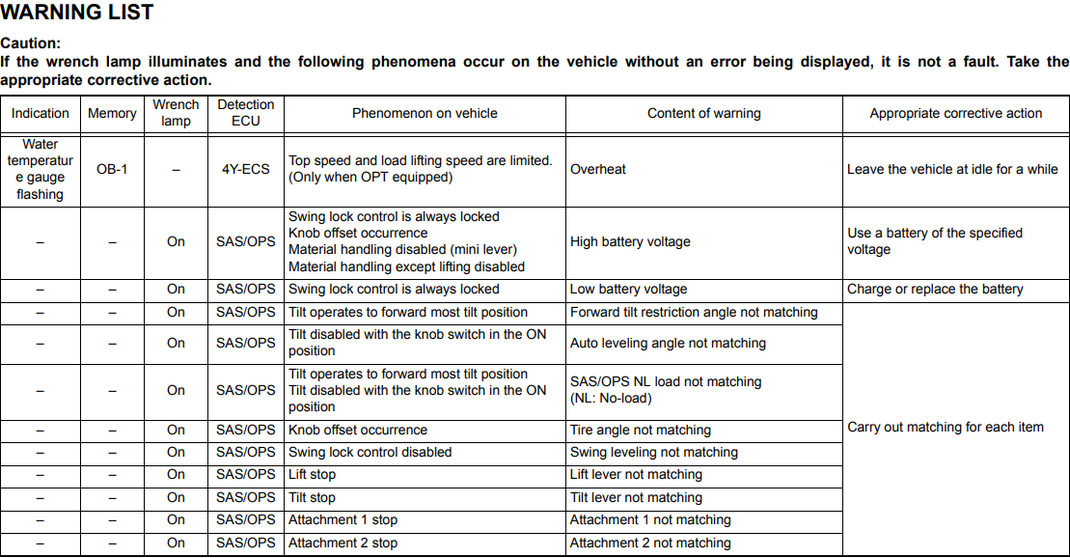

Caution:

If the wrench lamp illuminates and the following phenomena occur on the vehicle without an error being displayed, it is not a fault. Take the appropriate corrective action.

|

Indication |

Memory |

Wrench lamp |

Detection ECU |

Phenomenon on vehicle |

Content of warning |

Appropriate corrective action |

|

Water temperatur e gauge flashing |

OB-1 |

— |

4Y-ECS |

Top speed and load lifting speed are limited. (Only when OPT equipped) |

Overheat |

Leave the vehicle at idle for a while |

|

— |

— |

On |

SAS/OPS |

Swing lock control is always locked Knob offset occurrence |

High battery voltage |

Use a battery of the specified voltage |

|

— |

— |

On |

SAS/OPS |

Swing lock control is always locked |

Low battery voltage |

Charge or replace the battery |

|

— |

— |

On |

SAS/OPS |

Tilt operates to forward most tilt position |

Forward tilt restriction angle not matching |

Carry out matching for each item |

|

— |

— |

On |

SAS/OPS |

Tilt disabled with the knob switch in the ON position |

Auto leveling angle not matching |

|

|

— |

— |

On |

SAS/OPS |

Tilt operates to forward most tilt position Tilt disabled with the knob switch in the ON position |

SAS/OPS NIL load not matching (NL: No-load) |

|

|

— |

— |

On |

SAS/OPS |

Knob offset occurrence |

Tire angle not matching |

|

|

— |

— |

On |

SAS/OPS |

Swing lock control disabled |

Swing leveling not matching |

|

|

— |

— |

On |

SAS/OPS |

Lift stop |

Lift lever not matching |

|

|

— |

— |

On |

SAS/OPS |

Tilt stop |

Tilt lever not matching |

|

|

— |

— |

On |

SAS/OPS |

Attachment 1 stop |

Attachment 1 not matching |

|

|

— |

— |

On |

SAS/OPS |

Attachment 2 stop |

Attachment 2 not matching |

- Manuals

- Brands

- Toyota Manuals

- Forklifts

- BT Levio W Series

- Product manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Product guide

W-series

LWE140

LWE160

LWE180

LWE200

LWE250

www.toyota-forklifts.eu

Related Manuals for Toyota BT Levio W Series

Summary of Contents for Toyota BT Levio W Series

-

Page 1

Product guide W-series LWE140 LWE160 LWE180 LWE200 LWE250 www.toyota-forklifts.eu… -

Page 2

This product guide applies to: Model F code TD code LWE140 838aa LWE160 838ab LWE180 838ac LWE200 839aa LWE250 840aa Document revision history: Edition date Changes April 2008 Next generation Low-lifters February 2011 Technical updates August, 2011 New family and series name Januare, 2012 Technical updates Part number: 749851-040… -

Page 3: Table Of Contents

Contents Reading instructions Product range information BT Levio W-series (Low-lifter Walkie Electric) … … …… …… … …… … …… 9 LWE140 … ………… …… … …… … …… … …… …… … …… … …… 11 LWE160 … ………… … …… …… … …… … …… … …… …… … …… 11 LWE180 ……

-

Page 4

Product details Operator environment … ……… …… … …… … …… … …… …… … …… 25 Battery covers and storage compartments …… … …… …… … …… … …… 30 Driving features/programming the truck … …… … …… …… … …… … …… 31 Motor and power pack ………… -

Page 5

Options Battery change from the side … …… … …… … …… … …… …… … …… 65 Battery change table … … …… …… … …… … …… … …… …… … …… 66 Extra battery cables … … …… …… … …… … …… … …… …… … …… 66 Battery change cable …… -

Page 6

Product guide – BT Levio W-series… -

Page 7

Reading instructions This product guide is designed as a point of reference. To facilitate searching for specific features, it has an index at the back. In some cases, information is avail- able in two different chapters. This applies especially to the Sales arguments and Product details chapters describing the various features and benefits of the truck. -

Page 8

Product guide – BT Levio W-series… -

Page 9: Product Range Information

Product range information Product range information BT Levio W-series (Low-lifter Walkie Electric) BT Levio W-series without platform is a complete low-lifter series for walkie applications. These machines are mainly used where space is limited and travel distances are relatively short. All models have a maximum speed of 6 km/h. LWE200 can, as an option, be equipped with operator platform.

-

Page 10

Product range information intended application: Type of truck Capacity Feature LWE = Low-lifter Walkie Electrical 140 = 1400 kg L = Low-lifter W = Walkie 160 = 1600 kg E = Electrical 180 = 1800 kg 200 = 2000 kg 250 = 2500 kg The model code indicates rated truck capacity. -

Page 11: Lwe140

Product range information LWE140 ● BT Castor link. ● 156 mm narrow fork carriage. ● Chassis width 726 mm. ● Small standard battery compartment only, 150 Ah battery. ● l measurement 481 mm. ● Ideal for applications in smaller shops and warehouses.

-

Page 12: Lwe180

Product range information LWE180 ● BT Castor link. ● 180 mm standard fork carriage. ● Chassis width 726 mm. ● Medium or large standard battery com- partment, 225/300 Ah battery. ● l measurement 538/588 mm. ● Ideal for applications in warehouses and distribution centres.

-

Page 13: Lwe250

Product range information LWE250 ● BT Castor link. ● 180 mm standard fork carriage. ● Reinforced fork carriage. ● Chassis width 726 mm. ● Medium or large standard battery com- partment, 225/300 Ah battery. ● Large battery with battery towards the side, 260 Ah battery.

-

Page 14

Product range information Product guide – BT Levio W-series… -

Page 15: Applications

Applications Applications Walking There is always an LWE truck version that is optimised for the application no matter whether this involves loading/unloading of lorries, horizontal transport and/ or order picking. These trucks are typically used in warehouses/distribution cen- tres, industrial applications and shops/supermarkets with short to medium transport distances (aprox.

-

Page 16: Industry

Applications Industry Industrial applications require trucks with a high level of reliability. Goods must always be in the right place when needed. An increasing trend at many manufacturing companies is to reduce ware- house surfaces and intensify incoming deliveries. Although incoming deliveries may be frequent, usage intensity in these kinds of applications is lower compared to use in warehouses and distri- bution centres.

-

Page 17: Shops/Supermarkets

Applications Shops/supermarkets In shops and supermarkets, the trucks are often operated by inexperienced staff, and they may even be left unattended on shop floors among customers and children. This environment requires an easy-to-use truck designed to prevent unauthorised use. The LWE trucks feature simple operation, and they have a programmable switch-off timer.

-

Page 18: Which Truck For Which Application

Applications Which truck for which application? The following factors determine which model is suited for a given application: — Load carrier and load centre distance — Capacity — Usage intensity — Travel distances — Aisle widths — Ramps/slopes — Floor conditions It is also recommended to explore environmental requirements and future plans, for example to choose a truck that will not become obsolete when the company expands.

-

Page 19: Sales Arguments

Sales arguments Sales arguments In fall 2007, BT carried out market research with participation from 300 respond- ents across Europe, all of them potential customers. The results from this survey points to three important criteria for this kind of truck: ●…

-

Page 20: Simplicity

Sales arguments Simplicity These trucks are regarded as a tool. The intention is that both experienced and in- experienced operators should be able to use them. The following features make the LWE series trucks easy to operate: Manoeuvrability Feature ● The LWE trucks has a 5-point wheel configura- tion, i.e.

-

Page 21

Sales arguments View Feature The LWE trucks have a well-arranged ex- ternal design with superior operator view thanks to: ● A compact truck body that is lower on the fork side. ● Optimum distance to the truck with the operator sufficiently close to the truck for an unobstructed view. -

Page 22: Safety

Sales arguments Safety A safe truck prevents injuries and reduces costly damage to goods and the truck. The LWE series trucks come with a number of features that makes them safe in use. Operator safety Feature ● The distance to the operator’s feet is consider- able and floor clearance is 35 mm.

-

Page 23: Durability

Sales arguments Durability A truck that cannot be used costs money. On one hand the truck must always be available when needed in order for business to continue as usual and remain ef- ficient, while on the other hand service costs often represent a significant share of total truck costs during the truck’s life cycle.

-

Page 24

Sales arguments Benefit By designing for durability to eliminate causes of trouble, the following has been achieved: ● Unscheduled downtime that causes business interruptions has been reduced. ● Unnecessary repair costs have been reduced. ● Truck service life has been extended. Quick and easy service Feature In the design of the LWE trucks, a high level of serviceability was a key focus:… -

Page 25: Product Details

Product details Product details Operator environment The LWE trucks are primarily designed for operators walking alongside the truck and not standing on a platform, however, the LWE200 can be ordered with optional platform. Tiller arm and controls There are two versions of the tiller arm for the LWE series. One is designed for the walkie versions while the other is designed for the platform versions with the op- erator riding onboard.

-

Page 26

Product details Feature All controls are within easy reach and not placed too close together. The truck and all truck opera- tions can be operated with a single hand, left or right, as preferred. Benefit All controls are within immediate reach to reduce the risk of repetitive strain injury while opening up the possibility of productivity gains thanks to improved efficiency. -

Page 27

Product details Benefit No matter whether the truck is protected by a PIN code or ID unit: ● The truck can always be guarded against unauthorised use. ● Up to ten different operator settings can be stored in truck memory. Some companies prefer a physical key, in case an ID key, for truck access in order to keep track of who is using the trucks, especially in cases where external opera- tors need to temporarily use the truck, while others prefer access via PIN codes that… -

Page 28

Product details Feature When upright, the arm remains within the truck profile. Benefit The tiller arm does not require any space when left in the upright position, a clear advantage in very tight spaces. Feature The tiller arm features safety reversing. When the safety reversing switch is pushed, the trucks stops and immediately reverses in the other direction. -

Page 29

Product details Display The display shows battery status, total travel time and error messages. The display is also used to program operator parameters. Normal- ly, battery capacity is displayed as a percentage (%), but can when needed be replaced by error codes or operator parameters. -

Page 30: Battery Covers And Storage Compartments

Product details Benefit ● The operator can quickly confirm whether something is wrong with the truck, and he can in some cases correct it by restarting the truck. ● If intervention by a service technician is required, he can be informed about what’s wrong with the truck before arriving on site.

-

Page 31: Driving Features/Programming The Truck

Product details Driving features/programming the truck The LWE trucks are highly manoeuvrable and offer indi- vidual setting options for the operators. Settings that the operator can change himself are called operator parame- ters. The trucks also have a machine register in which set- tings only can be changed by a service technician.

-

Page 32

Product details Operator parameters To reprogram operator-specific parameters (if the change is permitted), proceed as follows: ● Press the horn button and keep it pressed while starting the truck using either PIN code entry or the ID unit. ● Release the horn button when the display shows “P”. The parameter symbol on the display lights. -

Page 33

Product details Feature It is possible to adapt the settings for speed, acceleration and braking characteris- tics to the operator’s level of experience and/or preferences. The truck can store up to ten different settings. Benefit By adapting the truck to the operator and/or the application, damage caused by in- experienced operators can be reduced while maximum productivity can be achieved with experienced operators. -

Page 34

Product details Automatic switch-off For more information regarding automatic switch-off, see the Service manual. Feature A service technician can set the desired time in- terval for truck switch-off in case the truck is left unattended. This time can be set to either 4 h or in the range of 1-20 minutes in increments of one minute. -

Page 35

Product details Brakes During normal travel, the motor is used to brake the truck, however, it also has an electromechanical parking brake which is applied whenever the truck is not in use. The parking brake can be released by to screws. See service manual for more information. -

Page 36: Motor And Power Pack

Product details Feature When the speed control is released to the neutral position or when the travel direc- tion changes, the motor brake is automatically applied. Benefit This makes truck travel more gentle and reduces brake plate wear. Feature During normal truck travel when the motor is used to brake the truck, energy is regenerated and returned to the battery every time the truck brakes.

-

Page 37

Product details AC drive motor The size of the motor depends on the truck: ● The LWE140, LWE160 and LWE180 use 1.0 kW drive motors. ● The LWE200 and LWE250 use 1.5 kW drive motors. Feature The drive motor is permanentnly mounted, and the motor does not move when the drive wheel turns. -

Page 38

Product details BT Powerdrive system The BT Powerdrive system on the LWE series is a unique combination of contact- less controls, CAN bus communication (CAN = Controller Area Network) and AC drive motor. Feature Contactless controls Benefit High reliability and reduced downtime thanks to the reduced number of moving parts and wear points. -

Page 39: Drive Wheel

Product details Drive wheel The drive wheel diameter is 230 mm. The LWE models offer four different mate- rial types. Drive wheel material The choice of drive wheel is a matter of balancing price, road holding characteris- tics and load handling performance. Four different types of materials are available: Topthane, Vulkollan, Powerfriction and Vulkollan mixed with sand.

-

Page 40

Product details 3. Powerfriction Feature All models can be ordered with Powerfriction drive wheels. This is a non-marking material with high friction coefficient. Benefit Powerfriction provides excellent grip, even on moist surfaces, and has superior wear characteristics. It does not leave marks on floors. 4. -

Page 41

Product details Drive wheel bracket All models feature fixed mounting of the drive wheel with suspended castor wheels. For details, please refer to Castor wheels and BT Castor link. Feature The LWE trucks have a 5-point wheel con- figuration with the drive wheel in the cen- tre. -

Page 42: Electronic Components

Product details Electronic components A general design objective of the LWE series, was to use as few electric compo- nents and cables as possible, while remaining parts are optimally protected against dirt, humidity, impacts, etc. Feature MQS (Micro Quadlok System) terminals are used throughout.

-

Page 43: Cover

Product details Cover Feature The cover is made of a highly resistant ABS material and is secured with only two screws. Two different covers exist, one for the walkie models and one for trucks with the platform op- tion. Benefit The cover is easy to remove and provides easy access to truck components.

-

Page 44

Product details Feature The lower part of the frame is compression- moulded. Benefit The moulding makes the truck more rigid while it absorbs impacts in an area where it is most needed, thus protecting the various truck func- tions. Feature Floor clearance, i.e. -

Page 45: Castor Wheels

Product details Castor wheels The castor wheels have a width of 50 mm. It is possible to select between Vulkollan and Polyurethane as castor wheel material. Depending on the application, the load on the wheel suspension is handled differently. 3 different types of BT Castor Link are available, but they all rely on the same basic principle.

-

Page 46

Product details Feature When the truck turns or passes a bump, pressure increases on one castor wheel as a result of compression of the spring. Thanks to the torsion tube, the other spring will compress by an identical amount. Benefit The truck remains stable and will never start to rock and travel like a ‘walking duck’, a classic phenomenon when spring forces do not interact. -

Page 47: Fork Carriage

Product details Fork carriage As far as the fork carriage is concerned, all bushings and axles, both classic prob- lem sources, have been improved. This chapter describes these parts together with the forks and fork wheels. Two fork carriages are used, narrow and standard. Feature Narrow fork carriage with 156 mm wide forks.

-

Page 48

Product details Axles and bushings Because bushings and axles are highly vulnerable parts, new high-quality materials have been developed for the LWE and SWE truck series. The results from truck life cycle tests have been very positive. Feature The bushings are made from Teflon-coated composite material. Benefit Teflon-coated composite bushings offer extended length of service and do not re- quire lubrication. -

Page 49: Battery Compartments, Batteries And Chargers

Product details Battery compartments, batteries and chargers When selecting the battery, these aspects should be considered: ● Physical limitations of the battery compartment – information on battery com- partment sizes is available in the Technical information chapter. ● Minimum and maximum weight –- these weights are indicated in the Technical information chapter.

-

Page 50

Product details Feature It is possible to select a desired battery compartment size. On the larger models, battery replacement to the side is available as an option. Benefit The truck can be optimised for the intended application. For higher intensive ap- plications, lateral battery replacement is a recommended option. -

Page 51

Product details Battery connector and charging To charge the battery, disconnect the battery connector and connect it to the battery charger. The battery connector should also be disconnected in the following situa- tions to cut the power supply: ● In the event of an accident. ●… -

Page 52

Product details Feature Different types of chargers provide different characteristics: ● Conventional, unregulated chargers are sensitive to line voltage fluctuations. As a result, the charging duration can vary, however, these chargers are cost-effec- tive. ● HF chargers are not as sensitive to fluctuations in the line voltage, and they are able to carefully control the charging process and as a result the charging dura- tion. -

Page 53: Technical Information

Technical information Technical information Dimensions and performance figures x measurement The x measurement is the distance back●of●fork●to●the●fork●wheel●centre. For trucks with bogie wheels, it is measured from back●of●fork●to●fork●bogie-wheel● centre. Usually this measurement is available in the Product information. l measurement The l measurement is the Total●fork●length. measurement The l measurement is the Truck●length●including●back●of●fork.

-

Page 54

Technical information u measurement The u measurement is the distance between fork● tip● and● the● wheel-fork● pivot● point. T measurement The measurement from●back●of●forks●to●the●wheel●fork●pivot●point is called the T measurement. The T measurement can be calculated with the formula: T = l -u As an example the u and T measurements are important for long side handling of pallets. -

Page 55

Technical information Standard fork length tables LWE140/160 X down, Fl-u+119 X up, Fl-u+64 1000 1070 1120 1150 1200 1220 1019 1370 1085 1204 1149 1450 1165 1284 1229 1520 1235 1354 1299 LWE180/200/250 X down, Fl-u+116 X up, Fl-u+59 1000 1050 1070 1100… -

Page 56

Technical information e, b and b measurements LWE140 LWE160 LWE180 LWE200 LWE250 measurement, height of fork in lowered position measurement, height of fork in raised position. e measurement, fork width measurement, width over forks The b measurement is referred to as the width●over●forks. This measurement must suit the pallets to be handled by the truck. -

Page 57: Aisle Width Requirement

Technical information , turning radius The turning radius is the necessary Distance●to●turn●the●truck●around●a●virtual● point●referred●to●as●the●turning●centre with forks raised. The product informa- tion provides Wa measurements for all LWE truck versions. – Aisle width requirement The aisle width requirement can be described as the space required by the truck to pick a pallet from a pallet rack, reverse out in the aisle, turn and proceed down the aisle.

-

Page 58: Aisle Width Requirements

Technical information Aisle width requirements Truck Battery comp. Aisle width for pallets: LWE140 small 1420 1842 1000×1200 longside handling small 1420 1892 800×1200 shortside handling Truck Battery comp. Aisle width for pallets: LWE160 small 1420 1842 1000×1200 longside handling small 1420 1892 800×1200 shortside handling…

-

Page 59

Technical information Calculating A according to the standard, LWE range ● The values are from the Product information sheet for LWE200. Standard: A = 1447 + (1200 — 898) + 2×100 = 1949 Length of pallet must be substituted by total fork length Standard: A = 1447+ (1150 — 898) + 2×100 = 1899… -

Page 60: Pallets And Pallet Sizes

Technical information Pallets and pallet sizes 1200 Euro pallet 382,5 382,5 ● Outer dimensions: 800 × 1200 mm ● Pallet height: 144 mm 227,5 227,5 ● Height, fork entries: 100 all four sides ● Corners: 45° ● Pallet weight: approximately 27 kg ●…

-

Page 61: Choosing The Optimal Fork Specification

Technical information Choosing the optimal fork specification When forks suited for a pallet or a specific roll container, these items should be considered: ● The b measurement must suit the pallet /roll container to enable positioning of the forks between the pallet legs or between the wheels of the roll container. Example: With Width over Forks 450 mm and Fork Width 180 mm, only 90 mm remains between the forks and the truck will not be able to handle Euro pallets or Chep pallets.

-

Page 62: Battery Weights

Technical information Battery weights LWE140 Batt. compartment Min. batt. weight kg Max. batt. weight kg Capacity Ah Volt V Size L*W*H mm Small 651 x 150 x 570 LWE160 Batt. compartment Min. batt. weight kg Max. batt. weight kg Capacity Ah Volt V Size L*W*H mm Small 651 x 150 x 570 Medium…

-

Page 63: Battery And Charger

Technical information Battery and charger Information on Hawker Evolution GEL batteries Hawker Evolution GEL batteries is the only type of valve-regulated batteries of- fered for the trucks in the LWE series. Please note the following if selecting a bat- tery of this type for the truck: ●…

-

Page 64

Technical information Product guide – BT Levio W-series… -

Page 65: Options

Options Options To adapt the truck to customer preferences, a number of options are available. Battery change from the side Battery roller bed which enables lateral battery replacement (only for trucks with a large bat- tery compartment). Not available for LWE140, LWE160 and LWE180.

-

Page 66: Battery Change Table

Options Battery change table To facilitate battery change from the side, an exter- nal battery change table is also available. The height from the floor to the top of the rollers is adjustable. The battery change table measurments are 834 x 912 mm.

-

Page 67: Built-In Charger

Options Built-in charger When connected to 230 V, the charger has a capacity of 30 A.It is self-adjusting and can be used for voltages between 90 V and 255 V AC, 45 to 400 Hz. For voltages under 200 V, the output current will be reduced. Freely ventilated batteries up to 320 Ah and valve regulated batteries from 134 to 213 Ah can be charged.

-

Page 68: Spacer For Long Side Pallet Handling

Options Feature Any error codes generated by the battery charger are displayed on the display. Benefit This simplifies fault diagnosis if required. Feature When the built-in charger is used, it is not possible to charge the battery unless the battery cover is opened since the power cord needs to be pulled out from behind the cover.

-

Page 69: Truck Log Systems

Truck log systems Toyota I-site Toyota I-site is a truck log and fleet management system that provides possibili- ties to monitor truck usage and operator performance. Toyota I-site is offered a monthly fee basis where we provide a continual process of analysis and consul- tancy to customers and give them access to our knowledge and skills to help us build customer relations.

-

Page 70

Options If the shock sensor is included in the system, information about collisions and im- pacts can be viewed. By monitoring truck usage and operator performance, customers can improve op- erations and reduce cost. Access to different levels of information can be set for different users/functions in the company. -

Page 71: Integrated E-Bar With Optional Accessories

Options Integrated E-bar with optional accessories All trucks in the LWE series, except for those with small battery compartment, can be fitted with an optional E-bar. This is BT’s standard solution for mounting a writing holder, plastic film holder, computer terminal, PC, scanner or other electronic equipment required onboard the truck.

-

Page 72: Turtle Button

Options Turtle button The turtle button allows temporary reduction of speed. The default setting for speed reduction is – 50 %, i.e. the travel speed will be reduced to 3 km/h. If necessary, this can be reprogrammed by a service technician. Feature When the turtle button is pressed once, the truck enters the turtle mode and travels at reduced speed.

-

Page 73: Operator Platform

Options Operator platform An operator platform is a useful option if the travel distances are a bit longer and the operator wants to have the comfort of a stand-on platform. The LWE series offers two different platform types, one with a rubber mat and automatic fold-up and a cold-store version with a checkered plate and also automatic fold-up.

-

Page 74

Options Feature The cold-store version of the platform uses a checkered plate. Benefit The checkered plate assures good friction even in cold stores and also in foodstuff applications where operators often wear wet or slippery shoes. Feature The platform is secured to a frame with rounded corners. Benefit The frame offers numerous benefits: ●… -

Page 75: Load Support

Options Load support The optional load support is attached to the back of the forks and is available on all LWE trucks. Feature The load support has a height of 1500 mm (from the top of the forks). Benefit This added support protects the operator and goods.

-

Page 76: Rubber Border

Options Rubber border A rubber border is available for all BT Levio W-series models. The trucks can be ordered with a rubber border instead of the standard steel border to allow high gradient ramp handling ability. The rubber border is especially suited for applications with high thresholds, curbs and ramps with high gradients.

-

Page 77: Appendix

Appendix Appendix Environmental work within BT The BT trucks are produced at manufacturing sites where environmental issues are in focus. Waste management and reduction of hazardous chemicals used in production are natural parts of the everyday environmental work. We have been ISO 14001 certified since 1997, and in our continuous environmental work we put effort into reducing energy consumption on all levels, while we work with preven- tive actions to reduce pollution risks and the risk of biological danger.

-

Page 78: Focus On Quality Within Bt

Appendix Focus on quality within BT The Toyota Way is based on the Guiding Principles at Toyota. Its five core values express the beliefs and values used in the daily work: Challenge To maintain a long-term vision and meet all challenges with the courage and crea- tivity needed to realise that vision.

-

Page 79

Appendix Products and components are tested and evaluated throughout the development process, both in lab environments and field tests. As a complement to calculations, structural tests as well as life time tests are performed. Apart from the functional testing and control made on all products before delivery, product quality is continuously monitored during manufacturing through welding audits on components and product audits on completed trucks. -

Page 80: Certificates

Appendix Certificates Product guide – BT Levio W-series…

-

Page 81

Appendix Product guide – BT Levio W-series…

- Manuals

- Brands

- Toyota Manuals

- Forklifts

- BT Levio W Series

- Product manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Product guide

W-series

LWE140

LWE160

LWE180

LWE200

LWE250

www.toyota-forklifts.eu

Related Manuals for Toyota BT Levio W Series

Summary of Contents for Toyota BT Levio W Series

-

Page 1

Product guide W-series LWE140 LWE160 LWE180 LWE200 LWE250 www.toyota-forklifts.eu… -

Page 2

This product guide applies to: Model F code TD code LWE140 838aa LWE160 838ab LWE180 838ac LWE200 839aa LWE250 840aa Document revision history: Edition date Changes April 2008 Next generation Low-lifters February 2011 Technical updates August, 2011 New family and series name Januare, 2012 Technical updates Part number: 749851-040… -

Page 3: Table Of Contents

Contents Reading instructions Product range information BT Levio W-series (Low-lifter Walkie Electric) … … …… …… … …… … …… 9 LWE140 … ………… …… … …… … …… … …… …… … …… … …… 11 LWE160 … ………… … …… …… … …… … …… … …… …… … …… 11 LWE180 ……

-

Page 4

Product details Operator environment … ……… …… … …… … …… … …… …… … …… 25 Battery covers and storage compartments …… … …… …… … …… … …… 30 Driving features/programming the truck … …… … …… …… … …… … …… 31 Motor and power pack ………… -

Page 5

Options Battery change from the side … …… … …… … …… … …… …… … …… 65 Battery change table … … …… …… … …… … …… … …… …… … …… 66 Extra battery cables … … …… …… … …… … …… … …… …… … …… 66 Battery change cable …… -

Page 6

Product guide – BT Levio W-series… -

Page 7

Reading instructions This product guide is designed as a point of reference. To facilitate searching for specific features, it has an index at the back. In some cases, information is avail- able in two different chapters. This applies especially to the Sales arguments and Product details chapters describing the various features and benefits of the truck. -

Page 8

Product guide – BT Levio W-series… -

Page 9: Product Range Information

Product range information Product range information BT Levio W-series (Low-lifter Walkie Electric) BT Levio W-series without platform is a complete low-lifter series for walkie applications. These machines are mainly used where space is limited and travel distances are relatively short. All models have a maximum speed of 6 km/h. LWE200 can, as an option, be equipped with operator platform.

-

Page 10

Product range information intended application: Type of truck Capacity Feature LWE = Low-lifter Walkie Electrical 140 = 1400 kg L = Low-lifter W = Walkie 160 = 1600 kg E = Electrical 180 = 1800 kg 200 = 2000 kg 250 = 2500 kg The model code indicates rated truck capacity. -

Page 11: Lwe140

Product range information LWE140 ● BT Castor link. ● 156 mm narrow fork carriage. ● Chassis width 726 mm. ● Small standard battery compartment only, 150 Ah battery. ● l measurement 481 mm. ● Ideal for applications in smaller shops and warehouses.

-

Page 12: Lwe180

Product range information LWE180 ● BT Castor link. ● 180 mm standard fork carriage. ● Chassis width 726 mm. ● Medium or large standard battery com- partment, 225/300 Ah battery. ● l measurement 538/588 mm. ● Ideal for applications in warehouses and distribution centres.

-

Page 13: Lwe250

Product range information LWE250 ● BT Castor link. ● 180 mm standard fork carriage. ● Reinforced fork carriage. ● Chassis width 726 mm. ● Medium or large standard battery com- partment, 225/300 Ah battery. ● Large battery with battery towards the side, 260 Ah battery.

-

Page 14

Product range information Product guide – BT Levio W-series… -

Page 15: Applications

Applications Applications Walking There is always an LWE truck version that is optimised for the application no matter whether this involves loading/unloading of lorries, horizontal transport and/ or order picking. These trucks are typically used in warehouses/distribution cen- tres, industrial applications and shops/supermarkets with short to medium transport distances (aprox.

-

Page 16: Industry

Applications Industry Industrial applications require trucks with a high level of reliability. Goods must always be in the right place when needed. An increasing trend at many manufacturing companies is to reduce ware- house surfaces and intensify incoming deliveries. Although incoming deliveries may be frequent, usage intensity in these kinds of applications is lower compared to use in warehouses and distri- bution centres.

-

Page 17: Shops/Supermarkets

Applications Shops/supermarkets In shops and supermarkets, the trucks are often operated by inexperienced staff, and they may even be left unattended on shop floors among customers and children. This environment requires an easy-to-use truck designed to prevent unauthorised use. The LWE trucks feature simple operation, and they have a programmable switch-off timer.

-

Page 18: Which Truck For Which Application

Applications Which truck for which application? The following factors determine which model is suited for a given application: — Load carrier and load centre distance — Capacity — Usage intensity — Travel distances — Aisle widths — Ramps/slopes — Floor conditions It is also recommended to explore environmental requirements and future plans, for example to choose a truck that will not become obsolete when the company expands.

-

Page 19: Sales Arguments

Sales arguments Sales arguments In fall 2007, BT carried out market research with participation from 300 respond- ents across Europe, all of them potential customers. The results from this survey points to three important criteria for this kind of truck: ●…

-

Page 20: Simplicity

Sales arguments Simplicity These trucks are regarded as a tool. The intention is that both experienced and in- experienced operators should be able to use them. The following features make the LWE series trucks easy to operate: Manoeuvrability Feature ● The LWE trucks has a 5-point wheel configura- tion, i.e.

-

Page 21

Sales arguments View Feature The LWE trucks have a well-arranged ex- ternal design with superior operator view thanks to: ● A compact truck body that is lower on the fork side. ● Optimum distance to the truck with the operator sufficiently close to the truck for an unobstructed view. -

Page 22: Safety

Sales arguments Safety A safe truck prevents injuries and reduces costly damage to goods and the truck. The LWE series trucks come with a number of features that makes them safe in use. Operator safety Feature ● The distance to the operator’s feet is consider- able and floor clearance is 35 mm.

-

Page 23: Durability

Sales arguments Durability A truck that cannot be used costs money. On one hand the truck must always be available when needed in order for business to continue as usual and remain ef- ficient, while on the other hand service costs often represent a significant share of total truck costs during the truck’s life cycle.

-

Page 24

Sales arguments Benefit By designing for durability to eliminate causes of trouble, the following has been achieved: ● Unscheduled downtime that causes business interruptions has been reduced. ● Unnecessary repair costs have been reduced. ● Truck service life has been extended. Quick and easy service Feature In the design of the LWE trucks, a high level of serviceability was a key focus:… -

Page 25: Product Details

Product details Product details Operator environment The LWE trucks are primarily designed for operators walking alongside the truck and not standing on a platform, however, the LWE200 can be ordered with optional platform. Tiller arm and controls There are two versions of the tiller arm for the LWE series. One is designed for the walkie versions while the other is designed for the platform versions with the op- erator riding onboard.

-

Page 26

Product details Feature All controls are within easy reach and not placed too close together. The truck and all truck opera- tions can be operated with a single hand, left or right, as preferred. Benefit All controls are within immediate reach to reduce the risk of repetitive strain injury while opening up the possibility of productivity gains thanks to improved efficiency. -

Page 27

Product details Benefit No matter whether the truck is protected by a PIN code or ID unit: ● The truck can always be guarded against unauthorised use. ● Up to ten different operator settings can be stored in truck memory. Some companies prefer a physical key, in case an ID key, for truck access in order to keep track of who is using the trucks, especially in cases where external opera- tors need to temporarily use the truck, while others prefer access via PIN codes that… -

Page 28

Product details Feature When upright, the arm remains within the truck profile. Benefit The tiller arm does not require any space when left in the upright position, a clear advantage in very tight spaces. Feature The tiller arm features safety reversing. When the safety reversing switch is pushed, the trucks stops and immediately reverses in the other direction. -

Page 29

Product details Display The display shows battery status, total travel time and error messages. The display is also used to program operator parameters. Normal- ly, battery capacity is displayed as a percentage (%), but can when needed be replaced by error codes or operator parameters. -

Page 30: Battery Covers And Storage Compartments

Product details Benefit ● The operator can quickly confirm whether something is wrong with the truck, and he can in some cases correct it by restarting the truck. ● If intervention by a service technician is required, he can be informed about what’s wrong with the truck before arriving on site.

-

Page 31: Driving Features/Programming The Truck

Product details Driving features/programming the truck The LWE trucks are highly manoeuvrable and offer indi- vidual setting options for the operators. Settings that the operator can change himself are called operator parame- ters. The trucks also have a machine register in which set- tings only can be changed by a service technician.

-

Page 32

Product details Operator parameters To reprogram operator-specific parameters (if the change is permitted), proceed as follows: ● Press the horn button and keep it pressed while starting the truck using either PIN code entry or the ID unit. ● Release the horn button when the display shows “P”. The parameter symbol on the display lights. -

Page 33

Product details Feature It is possible to adapt the settings for speed, acceleration and braking characteris- tics to the operator’s level of experience and/or preferences. The truck can store up to ten different settings. Benefit By adapting the truck to the operator and/or the application, damage caused by in- experienced operators can be reduced while maximum productivity can be achieved with experienced operators. -

Page 34

Product details Automatic switch-off For more information regarding automatic switch-off, see the Service manual. Feature A service technician can set the desired time in- terval for truck switch-off in case the truck is left unattended. This time can be set to either 4 h or in the range of 1-20 minutes in increments of one minute. -

Page 35

Product details Brakes During normal travel, the motor is used to brake the truck, however, it also has an electromechanical parking brake which is applied whenever the truck is not in use. The parking brake can be released by to screws. See service manual for more information. -

Page 36: Motor And Power Pack

Product details Feature When the speed control is released to the neutral position or when the travel direc- tion changes, the motor brake is automatically applied. Benefit This makes truck travel more gentle and reduces brake plate wear. Feature During normal truck travel when the motor is used to brake the truck, energy is regenerated and returned to the battery every time the truck brakes.

-

Page 37

Product details AC drive motor The size of the motor depends on the truck: ● The LWE140, LWE160 and LWE180 use 1.0 kW drive motors. ● The LWE200 and LWE250 use 1.5 kW drive motors. Feature The drive motor is permanentnly mounted, and the motor does not move when the drive wheel turns. -

Page 38

Product details BT Powerdrive system The BT Powerdrive system on the LWE series is a unique combination of contact- less controls, CAN bus communication (CAN = Controller Area Network) and AC drive motor. Feature Contactless controls Benefit High reliability and reduced downtime thanks to the reduced number of moving parts and wear points. -

Page 39: Drive Wheel

Product details Drive wheel The drive wheel diameter is 230 mm. The LWE models offer four different mate- rial types. Drive wheel material The choice of drive wheel is a matter of balancing price, road holding characteris- tics and load handling performance. Four different types of materials are available: Topthane, Vulkollan, Powerfriction and Vulkollan mixed with sand.

-

Page 40

Product details 3. Powerfriction Feature All models can be ordered with Powerfriction drive wheels. This is a non-marking material with high friction coefficient. Benefit Powerfriction provides excellent grip, even on moist surfaces, and has superior wear characteristics. It does not leave marks on floors. 4. -

Page 41

Product details Drive wheel bracket All models feature fixed mounting of the drive wheel with suspended castor wheels. For details, please refer to Castor wheels and BT Castor link. Feature The LWE trucks have a 5-point wheel con- figuration with the drive wheel in the cen- tre. -

Page 42: Electronic Components

Product details Electronic components A general design objective of the LWE series, was to use as few electric compo- nents and cables as possible, while remaining parts are optimally protected against dirt, humidity, impacts, etc. Feature MQS (Micro Quadlok System) terminals are used throughout.

-

Page 43: Cover

Product details Cover Feature The cover is made of a highly resistant ABS material and is secured with only two screws. Two different covers exist, one for the walkie models and one for trucks with the platform op- tion. Benefit The cover is easy to remove and provides easy access to truck components.

-

Page 44

Product details Feature The lower part of the frame is compression- moulded. Benefit The moulding makes the truck more rigid while it absorbs impacts in an area where it is most needed, thus protecting the various truck func- tions. Feature Floor clearance, i.e. -

Page 45: Castor Wheels

Product details Castor wheels The castor wheels have a width of 50 mm. It is possible to select between Vulkollan and Polyurethane as castor wheel material. Depending on the application, the load on the wheel suspension is handled differently. 3 different types of BT Castor Link are available, but they all rely on the same basic principle.

-

Page 46

Product details Feature When the truck turns or passes a bump, pressure increases on one castor wheel as a result of compression of the spring. Thanks to the torsion tube, the other spring will compress by an identical amount. Benefit The truck remains stable and will never start to rock and travel like a ‘walking duck’, a classic phenomenon when spring forces do not interact. -

Page 47: Fork Carriage

Product details Fork carriage As far as the fork carriage is concerned, all bushings and axles, both classic prob- lem sources, have been improved. This chapter describes these parts together with the forks and fork wheels. Two fork carriages are used, narrow and standard. Feature Narrow fork carriage with 156 mm wide forks.

-

Page 48

Product details Axles and bushings Because bushings and axles are highly vulnerable parts, new high-quality materials have been developed for the LWE and SWE truck series. The results from truck life cycle tests have been very positive. Feature The bushings are made from Teflon-coated composite material. Benefit Teflon-coated composite bushings offer extended length of service and do not re- quire lubrication. -

Page 49: Battery Compartments, Batteries And Chargers

Product details Battery compartments, batteries and chargers When selecting the battery, these aspects should be considered: ● Physical limitations of the battery compartment – information on battery com- partment sizes is available in the Technical information chapter. ● Minimum and maximum weight –- these weights are indicated in the Technical information chapter.

-

Page 50